Decanter centrifuge services

Alfa Laval’s comprehensive service offering can assist you in your decanter centrifuge optimization as your operations develop and change over time. As part of the service offering you find both decanter centrifuge optimization, troubleshooting and training, and more. Ensure outstanding performance from your Alfa Laval decanter and minimal total cost of ownership.

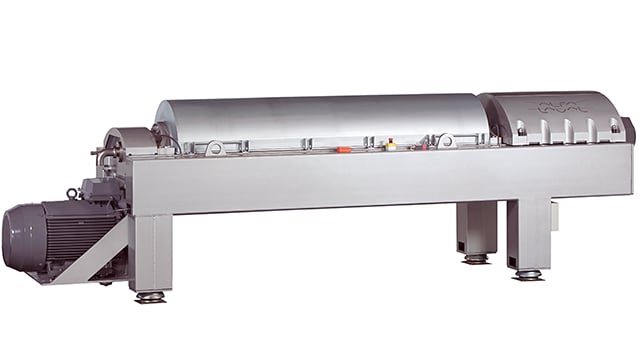

Aldec for sludge thickening and dewatering

2018-06-18 6504 kBAldec G3 Decanter centrifuges - Product leaflet.pdf Aldec G3 Decanter centrifuges - Product leaflet 2024

2018-06-18 7922 kBAldec Product Leaflet - High performance for sludge thickening and dewatering decanter centrifuges.pdf Aldec Product Leaflet 2024

2018-06-18 6504 kBAlfa Laval Aldec for sludge thickening and dewatering Decanter Centrifuge Product leaflet Alfa Laval Aldec Decanter Centrifuge Product leaflet 2024

2018-06-18 6504 kBAlfa Laval Aldec G3 Decanter Centrifuges

2018-06-18 6504 kBAlfa Laval Decanter Centrifuge Operating Principles.pdf Understand how a decanter centrifuge work.

2018-06-18 924 kBAlfa Laval Decanter Centrifuge Safety Instructions.pdf Read these safety instructions and this manual carefully before attempting to start, operate or service the decanter.

2018-06-18 250 kBAlfa Laval Decanter Maintenance Training Presentation.pdf An overview of training courses, benefits, optimal time for training, customer cases and frequently asked questions related to decanter maintenance training.

2018-06-18 357 kBAlfa Laval Decanter Power Plates Product Leaflet.pdf Reduce the power consumption of your decanters. See the range of Alfa Laval decanters Power Plates can be installed on, and 2 case studies.

2018-06-18 197 kBAlfa Laval Decanter Preventive Maintenance Presentation.pdf Offering description of decanter preventive maintenance services, benefits, optimal time for using preventive maintenance, customer cases and frequently asked questions.

2018-06-18 401 kBAlfa Laval Decanter Processing Training Presentation.pdf Offering description of wasterwater decanter process training services, benefits, optimal time for using processing training, customer cases and frequently asked questions.

2018-06-18 384 kBAlfa Laval Decanter Service Kit Presentation.pdf Decanter service kit description, benefits, optimal time for using it, customer cases and frequently asked questions.

2018-06-18 308 kBAlfa Laval Decanter Service Tool Presentation.pdf Decanter service tool description, benefits, optimal time for using it, customer cases and frequently asked questions.

2018-06-18 325 kBAlfa Laval Decanter Upgrade Presentation.pdf Decanter upgrade description, benefits, optimal time for upgrade, customer cases and frequently asked questions.

2018-06-18 343 kBAlfa Laval i-DW decanter centrifuge product leaflet.pdf Alfa Laval i-DW decanter centrifuge product leaflet

2018-06-18 347 kBAlfa Laval PANX palm oil decanter centrifuge product leaflet.pdf Alfa Laval PANX range of decanters are high-performance 3-phase decanters centrifuges for crude palm oil.

2018-06-18 1411 kBAlfa Laval Sigma Range Olive Oil Decanter Centrifuge.pdf Alfa Laval Sigma Range Olive Oil Decanter Centrifuge

2018-06-18 4147 kBFoodec 200.pdf

2018-06-18 875 kBFoodec 500.pdf

2018-06-18 155 kBFoodec 600.pdf

2018-06-18 1630 kBFoodec 800.pdf

2018-06-18 1639 kBi-Dec Decanter Centrifuges - Product leaflet i-Dec Decanter Centrifuges - Product leaflet 2024

2018-06-18 5628 kBLYNX 1000 - Drilling mud decanter.pdf

2018-06-18 79 kBLYNX 35 for slop oil treatment PEE00105EN.pdf

2018-06-18 58 kBLYNX 430 Decanter centrifuge for cost-effective slop oil treatment.pdf

2018-06-18 341 kBLYNX 730 product leaflet.pdf

2018-06-18 711 kBP1 product leaflet.pdf

2018-06-18 757 kBP2_decanter_centrifuge_range_PPI00120EN.pdf

2018-06-18 2106 kBP3 product leaflet.pdf P3 product leaflet

2018-06-18 443 kBProduct_Leaflet_CDNX_range_EN.pdf CDNX range - Product leaflet

2018-06-18 655 kBSG2 decanter centrifuge range PPI00109EN.pdf

2018-06-18 2364 kBSTNX decanter centrifuge.pdf

2018-06-18 485 kBWS 10 20 30 EFU00029EN.pdf

2018-06-18 1410 kBWS 40 60 EFU00030EN.pdf

2018-06-18 3816 kBX-series decanters PFT00316EN.pdf

2018-06-18 288 kBДекантерная центрифуга LYNX 35.pdf

2018-06-18 131 kBДекантерная центрифуга LYNX 40.pdf

2018-06-18 90 kBDecanter centrifuge troubleshooting

No matter what the cause, if a problem arises related to Alfa Laval equipment, Alfa Laval troubleshooters will get to the bottom of it and prevent future hold-ups.

Alfa Laval has more than 100 years of decanter centrifuge experience, which gives our troubleshooters a wealth of knowledge at their fingertips.

Who are Alfa Laval troubleshooters? Not everyone can work with decanter centrifuge troubleshooting at Alfa Laval. In order to qualify, a troubleshooter must possess:

- In-depth product knowledge

- Customer process understanding

- Practical experience

- Theoretical knowledge

- Material knowledge

- Automation know-how

Alfa Laval Remote Guidance can be a supplement to the existing way of delivering service to you at site. With our tool and process, our field service engineers and product experts can establish a merged reality via a video link sent to your mobile device on site.

Check out Alfa Laval's Connected IoT Services, which provides the fastest solution for decanter centrifuge troubleshooting, process optimization and predictive maintenance.

Connected services for decanters

Contact your local sales company to get troubleshooting assistance

Decanter centrifuge training

Skills and Knowledge Empower

When you buy Alfa Laval equipment, you buy peace of mind. But you must also rely on your equipment operators to get the job done. That's why competence development is invaluable to your everyday operations.

The more effectively your operators work with your Alfa Laval decanter centrifuge, the higher its reliability and the lower the costs of ownership.

Alfa Laval offers a broad range of decanter centrifuge training courses with a balanced mix of hands-on and theoretical training. The decanter centrifuge training programmes can focus on a particular product, industry and/or application. Tailor-made training can be offered based on your specific training needs for most industries. In some cases, e-Learning (self-study and webinars) is available, which is a fast, cost-efficient way to learn.

Contact us to learn more about decanter centrifuge training opportunities near you.

Explore maintenance training Explore wastewater process training

Global Test & Innovation Centre for Decanters

In our new Test & Innovation Centre we develop, test and optimize the next generation of decanters in a controlled environment. The centre is our global knowledge hub for Food & Water applications. The centre is located at Alfa Laval’s site in Søborg, Copenhagen, and currently covers an initial 2,000 square metres.

Read more about our decanter centrifuge innovation centre

Contact your local sales company to learn more about training opportunities

Spare parts

Spare Kits

Alfa Laval has Service Kits for planned maintenance, which have been developed based on years of experience. These include all the genuine spare parts required for a specific decanter service. Alfa Laval ensures that the kits contain the most up-to-date spare parts to ensure your equipment uses the latest technology available.

Spare Tools

Specially developed Service Tools protect decanters from faulty service and maximize performance.

Contact your local sales company for spare parts

Service Offerings

With an Alfa Laval Service Agreement, you ensure outstanding performance from your Alfa Laval decanter and minimal total cost of ownership. Tailored to your priorities and requirements, a Service Agreement is the ideal maintenance solution from the original manufacturer of your equipment.

Performance Audit - Decanter Centrifuge Optimization & Cost Savings

Extend your decanter capability with an Alfa Laval Performance Audit to get decanter centrifuge optimization and cost-savings. With an Alfa Laval Performance Audit, our global service and support experts help you get the best performance from your equipment.

Preventive Maintenance for Decanters

To keep a decanter working efficiently, a comprehensive preventive maintenance programme, tailored to meet specific customer requirements and budget, is the best choice.

Equipment Upgrades for Decanters

Improve decanter availability, process and performance by upgrading your decanter. Experience increased capacity, efficient operation, lower operating costs and longer service intervals.

Connected Services

Over the last 30 years, the internet has revolutionized the way humans interact. The interconnection of machines, sensors and various digital systems, commonly referred to as the internet of things (IoT), brings completely new possibilities to increase efficiency and add value for customers. With Connected Services, you’ll always know how your decanter is performing, why it isn’t, and how to correct the issue. That means more and better uptime - ensuring your investment is always able to perform as optimally as it was engineered to do.