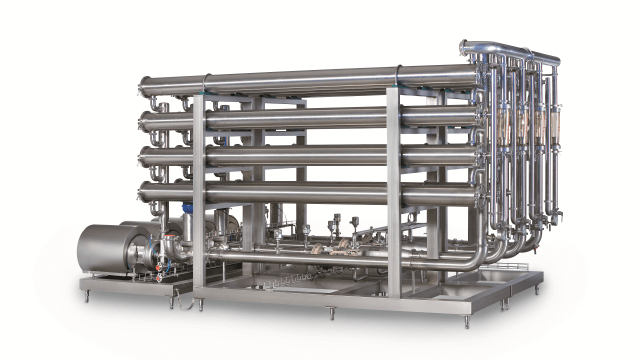

Ultrafiltration systems for animal blood processing

The Alfa Laval Pro-UF Plasma systems are cross-flow ultrafiltration (UF) membrane units of hygienic design. An ultrafiltration system specially prepared for ultrafiltration of blood for the concentration and purification of animal blood plasma. Minimized operating costs are ensured with the water saving Alfa Laval GreenClean cleaning process combined with lowered energy consumption.

New generation standard membrane ultrafiltration systems for sustainable blood plasma concentration

- Alfa Laval GreenClean technology providing reduction in CIP water consumption and optimal product and CIP displacement

- High degree of flexibility on production parameters and optional equipment available

- Possible direct feed of incoming plasma from HSS eliminating need for additional feed tank

- Up to 92% protein purity without use of diafiltration water

- All main components, including unique high-performance spiral membranes, manufactured by Alfa Laval

Ultrafiltration system - applications

- The Alfa Laval ultrafiltration system is ideal for the treatment of hygienically collected animal blood plasma sourced from bovine and pigs.

- Valuable proteins are concentrated stepwise when passing through several interconnected membrane stages.

- Purity of protein is improved when minerals pass through the membrane with the water.

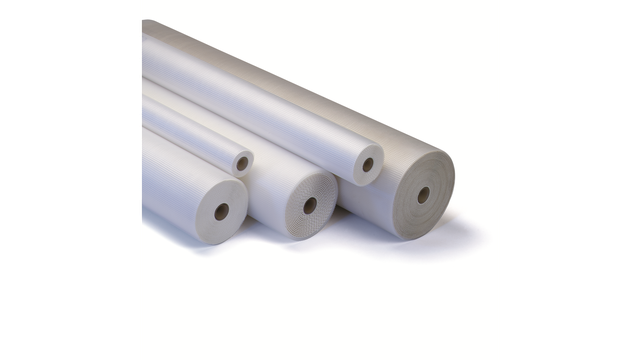

A broad choice of Alfa Laval membranes used in the ultrafiltration process:

UF-pHt™ membranes

Broad pH tolerance meets high temperature resistance

Made with a special polypropylene paper, these UF membranes can be used across a broad range of pH levels as well as high temperatures. This helps to increase both process flexibility and the hygiene of the membrane filtration system.

UF spiral membranes

Our UF spiral membranes are based on a unique construction of either polypropylene or polyester support material in a sanitary, full-fit design that provides optimum cleaning conditions.

How it works

How does the Pro-UF Plasma ultrafiltration system work?

Concentration and purification

The freshly separated blood plasma is concentrated and purified in a continuous filtration process, during which the valuable proteins are retained by the ultrafiltration membrane and incrementally concentrated (retentate) when passing through several interconnected membrane stages.

Minerals pass through the membrane with the water (permeate) which improves protein purity.

Ultrafiltration system options

The Alfa Laval Pro-UF Plasma systems are available with the following optional equipment:

- Refractometer (K-Patents) for Brix control of the concentrated plasma

- Pre-feed pump control

- Heat exchanger on the feed line to pre-heat the incoming plasma

- Retentate cooler to cool the concentrated plasma

- Heat exchanger in the retentate CIP line to heat the CIP solution

- Steam injection in the tank to heat the CIP solution

- Heat recovery from the retentate and permeate to heat the incoming plasma

- CIP dosing system for automatic CIP sequence with up to 5 agents for cleaning and sanitization

- External CIP valve system to clean the permeate, retentate and feed outlet lines

- The MCC panel and frequency inverters are supplied as standalone for installation in the MCC room

Over 50 years of experience

Membrane filtration is a clean technology. Benefit from our expertise. Alfa Laval’s experience within membrane filtration systems, cross-flow ultrafiltration and continuous membrane filtration dates back almost as far as the technology itself.

How can we help you?

Let’s discuss how we can help you achieve top quality products that comply with the many stringent requirements from both consumers and public authorities.