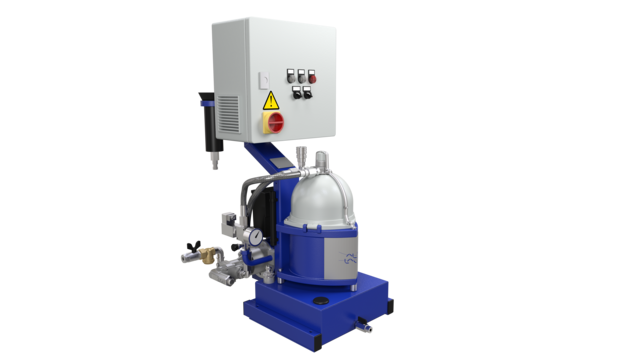

MIB

Streamline maintenance and reduce costs with the Alfa Laval MIB series centrifugal separation systems. Using advanced manufacturing, design and drive technologies, it's smaller and lighter than conventional solid-bowl models.

Innovation and ergonomics

- New design allows you to clean the bowl with the disc stack still in place

- Throughput capacity of up to 1250 l/h of gas oil, 1000 l/h of diesel oil and 300 l/h of steam turbine lube oil

- Direct drive with motor speed controlled by a frequency converter, eliminating gears and belts

- No lubrication required

- Small footprint allows installation in narrow spaces

How it works

Separation takes place in a rotating solid-wall bowl. Centrifugal force pushes water and solid particles outwards. Water collects in the seal, which drains into a channel underneath. Solids accumulate on the bowl wall and are easy to remove by hand.

Clean oil flows inwards and up to the paring disc. Since the clean oil is rotating, the stationary disc acts as a pump, forcing it through the outlet.

Choose the ideal system for your application

The MIB separator is available as a purifier or clarifier. If your application uses distillate or marine diesel oil, you should use it as a purifier. You can use it in either clarification or purification mode if you're cleaning lubricating oil.

Choose between standalone and module versions. The module has all equipment built in a compact unit. They're available in both 230V AC and 110V AC.

Impact of IMO 2020 on marine engine lubrication

With changes in marine fuel types, lubricant requirements need to be reassessed. To remove insolubles and water from the lube oil, centrifugal separators are ideal to promote engine longevity and efficiency, regardless of the fuel type used.