Merco

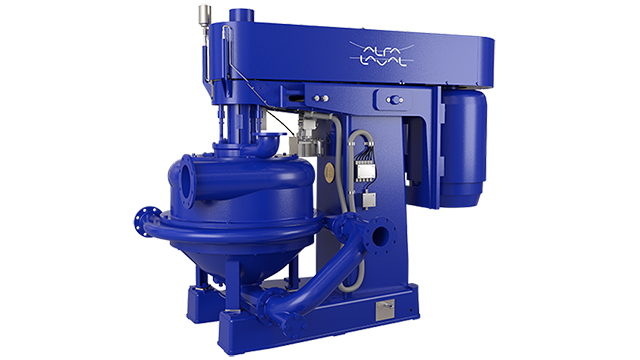

Alfa Laval is the leading supplier of process equipment and process lines to starch industry all over the world. More than half of starch produced each year throughout the world passes through Alfa Laval Merco separators. Developed particularly for starch production, Merco separator provides an ideal combination of high flow capacity and low energy consumption. Merco’s well-known sturdy design ensures long service life, reliable uptime and low maintenance costs.

Robustness and efficiency combined

- Increased separation capacity

- Simplified maintenance and service

- Easy installation

- Low power consumption

- Possibilities for upgrade of the older models

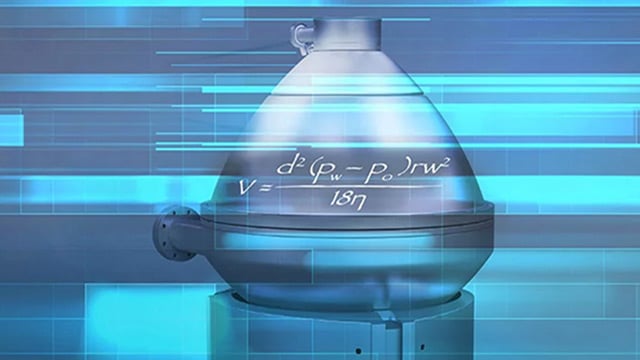

The Merco is a nozzle centrifuge designed for continuous discharge of solids, specially developed for the starch industry.

The centrifuge is equipped with a motor, a self-cleaning strainer for the feed, speed and vibration sensors, oil temperature sensors for the spindle bearings and the motor winding, a hydraulic power unit for the lifting hoist, a set of special tools and a standard set of spares.

Designed to meet starch processing requirements

The Merco range of starch separators differs from conventional multi-purpose nozzle centrifuges, specially developed to meet starch processing requirements. These involve high solids loads and continuous discharge, combined with a need to avoid nozzle blockages.

Merco nozzle centrifuges are now widely used in the starch industry for primary starch separation, gluten thickening, mill stream thickening and the clarification of middlings. As part of this, they are used for classifying, concentrating and washing solids and clarifying liquids that containing relatively high concentrations of solids.

The key feature of the Merco starch separator design is a special recirculation system in which solids can be recirculated to the nozzles at the edge of the bowl at the same time as wash water is added. This unique capability means users can adjust starch production settings while the system is operating simply by varying the nozzle draw-off.

The operator can change the split and the concentration by simply adjusting of the underflow draw-off valve in the discharge line. This provides a uniquely efficient way to control the starch separation process by determining exactly how much underflow is to be removed, how much is to be recycled back to the rotor and how much wash water is to be added.

This also makes it possible to use large-diameter nozzles that can deal with variations in feed concentration and help prevent blockages. This, in turn, makes the unit more versatile and makes it easy to vary procedures based on the characteristics of individual feed flows.

Our product range consists of two starch separator models - Merco 32 and Merco 38 - which can cover all the capacities and business demands at the milling plants.

Merco 32 starch separator

True working horse

- Smart design with long spindle and hanging bowl

- Stable high quality and high yield

- Patented power-saving nozzle design

- Low spare parts demand and cost

- Easy to keep the bowl clean

Merco 38 starch separator

High capacity starch centrifuge

- up to 30% capacity increase

- up to 25% power reduction

- Better yields at the same capacity and cleaner process water

- Max. bowl speed at 50 Hz - 2950 rpm

- Installed power - 225/260 kW

How to upgrade your Merco H-30 to Merco 32 starch separator

If you own a machine of older generation Merco H-30 separator, you can easily upgrade it to the latest modification - Merco 32 - by replacing the bowl. It will allow you to increase the plant capacity considerably at a lower capital cost than purchasing a new separator. A new bowl can be installed within one day and at a minimum installation cost.

Merco 32 Capacity Booster: simply replace your Alfa Laval Merco H-30 rotor assembly and feed inlet assembly with our new product Merco 32 rotor assembly and feed inlet assembly. Watch this video to see how easily it can be done with less investment.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.