Compabloc

With over 30,000 units handling tough duties worldwide, Compabloc is the market champion when it comes to heat transfer. Its compact design has been engineered for superior reliability and performance, making it easy to both service and install. Plus, our Compabloc family is 3-5 times more efficient than traditional shell-and-tube solutions and secures safe operation of up to 60 bar. Learn more about our range to find out how we have improved our process sustainability with you in mind.

Discover how you can improve sustainability

- Superior heat transfer and minimal fouling to provide exceptional thermal efficiency and energy savings

- Asymmetric flows handled easily with flexible flow configurations

- Crossing temperatures in a single unit maximizes energy recovery, reduces power bills, and boosts your process performance

- 100% mechanically cleanable with no crevices that can cause corrosion issues

- Fully confined graphite gasket and laser-welded plates to optimize reliability

Technical information

Find all relevant technical information about Compabloc including our unique innovations that set it apart from the rest.

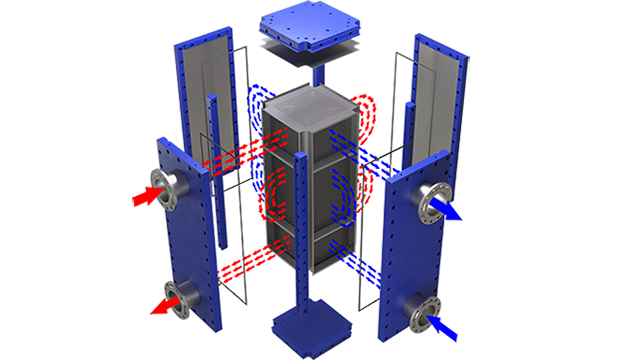

How does a Compabloc work? Learn about the working principle of the Compabloc heat exchanger, and watch explanatory animations and illustrations.

You can also read more details about 6 considerations for your selection process and discover the plate heat exchanger benefits of Alfa Laval Compabloc.

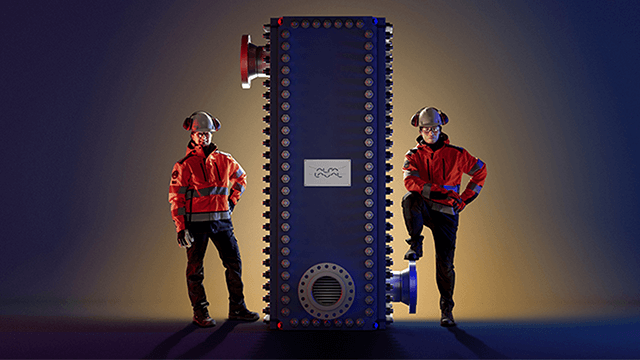

Meet our experts

Alfa Laval Compabloc is proven to improve efficiency and sustainability in some of the most demanding heat transfer duties all over the world. But when you choose Compabloc, you are ultimately choosing more than just the technology. You are choosing the people behind it: experienced experts with deep process knowledge and a global service presence. Listen to some of them directly about what makes Compabloc the true champion of heat exchange.

Why make the switch?

What makes Compabloc+ different?

How do we make service simple?

Common applications and positions for Compabloc

Compabloc can handle demanding positions and applications with duties that involve aggressive media, extreme temperatures and high pressures. Find out more about the applications and positions in which you can use the Compabloc heat exchanger.

References

See how we have helped numerous plants in demanding applications around the world improve thermal performance, increase production capacity and remove process bottlenecks within space constrains while at the same time lowering installation costs and many other benefits.

Service

Service

Energy-efficient and reliable technology, along with a partner you can count on for the long haul. Our robust, efficient and compact designs have a proven reputation for high reliability in some of the toughest process duties across industries. With added support from a worldwide network of local service experts, you can count on your welded plate-and-block heat exchanger delivering truly sustainable uptime .

Troubleshooting assistance

If you ever encounter a performance challenge or unexplained phenomenon, we can connect you with one of our trained and experienced troubleshooters who will suggest solutions and offer suggestions for further process improvements.

Ten top tips for Compabloc heat exchangers

Do you have a welded plate-and-block heat exchanger? We want to share our best practices for maintaining consistently high performance, maximum operational reliability, and exceptional energy efficiency. We’ve created a new series of videos that show you how to perform maintenance safely and how to keep your Compabloc heat exchangers in the best possible condition.