Heat recovery

Data centers have made many improvements towards sustainability over the last few decades. This covers everything from reducing power usage effectiveness (PUE) and carbon usage effectiveness (CUE), to improving water usage effectiveness (WUE). But, now it is time to take the next revolutionary leap for the data center industry.

By taking care of waste heat, data centers can also be energy suppliers. This not only increases overall profitability, but it also improves the metrics of their energy reuse effectiveness (ERE).

The cooling process is one of the highest contributors to electricity usage in your average data center. It also accounts for higher operational costs and significant environmental concerns due its carbon footprint. So, harnessing this energy in a heat recovery process will mean that the waste energy is used in other applications and the growing impact is reduced.

With that said, there are some challenges to recycling dater center heat, as the heating activity can often require a higher temperature than the cooling water found in your average data center. Luckily, with a heat pump, you can fix this problem and reach the required temperature.

What's best of all, it can actually benefit the cooling performance of your system!

Heat reuse opportunities

Data centers have the potential to contribute to creating a more sustainable environment with the right cooling technology inside. Thanks to the fast development of this technology, we are able to convert the waste heat emitted from IT equipment into a rage of temperatures for many new applications. In other words, we can improve data center heat recovery to accommodate the growing capacity per rack, reduce electricity usage in the industry, and improve overall carbon emissions.

With that, here are different cooling methods available, their corresponding temperatures, and examples of the heat reuse opportunities:

- Computer room air handling unit / Chilled water to air 30°C Learn more>>

- Rear door cooling 40°C Learn more>>

- Direct to chip cooling / Cold plate 45°C Learn more>>

- Immersion cooling 55°C Learn more>>

Direct heat recovery

When the process temperature requirements for waste heat from a dater center is low, it is possible to connect the consumer to the cooling loop without increasing temperature levels. This is an ideal scenario, as adding a heat pump to increase the temperature requires electricity.

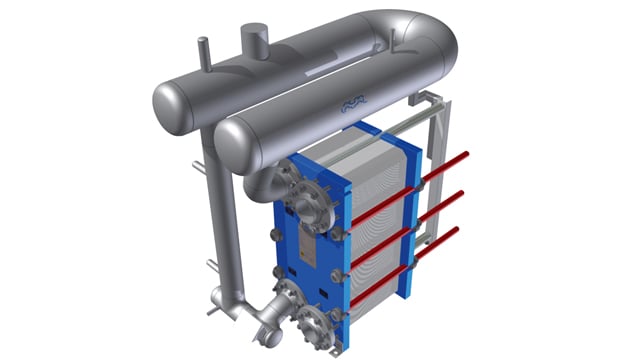

Thanks to the growing liquid-to-liquid cooling technology we can improve efficiency and recover more heat when the temperature demands are higher. Adding a plate heat exchanger is recommended here, as it helps avoid interference between two systems and acts as a system breaker.

Examples of applications that can use direct heat are space heating, green houses, insect farms, fish farms, algae farms, desalination plants, wood- and biomass-drying and much more.

Heat recovery using a heat pump

If the required process temperature is higher than the temperature of the cooling water from the data center, a heat pump can be connected to increase the temperature. A heat pump works as an inverted fridge; the cooling water from the data center is used to evaporate a synthetic freon or a natural refrigerant. The chosen refrigerant is pressurized in a compressor so that it can be released at a higher temperature in a condenser. This heat can then be used in the industry process, district heating water, or domestic hot water for example.

To maximize energy efficiency and minimize power consumption in the compressor, a heat pump with a high Coefficient of Performance (COP) should be used. The most sustainable solution, with the highest COP, is to use a natural refrigerant such as carbon dioxide or ammonia. Combine one of these natural refrigerants with a brazed or semi welded plate heat exchanger for the most energy efficient results.

In case of seasonal variations, a heat pump can be combined with other cooling solutions (such as free cooling or chillers) to achieve optimal system efficiency.

Multidimensional savings

The combination of waste heat recovery and a well designed plate heat exchanger will improve the cost efficiency and sustainability of a data center in many ways.

What's more, heat recovery solutions are key to accelerating the transition towards net-zero emissions. In this video you will learn about efficiency metrics and the role that waste heat recovery plays in creating a sustainable data center.

Heat recovery solutions

How do we design data centers on a more sustainable scale? Well, it is important to find the right temperatures that suit the cooling process as much as the heating process. We have the solution. By combining a heat pump, natural refrigerants, and an Alfa Laval plate heat exchanger you can achieve a higher COP (Coefficient Of Performance). This will allow you to reach the desired temperatures and enhance your cooling system performance at the same time. It's a win win.

At Alfa Laval we have the leading expertise to help you optimize your cooling and waste heat recovery. Watch this video of our experts, Christian Kempe and Jesper Olsen, to learn more about how to design sustainable data centers.

The benefits of plate heat exchangers

- Enable heat recovery

- Efficient system breaker to secure interference and responsibility

- Volume isolation

- Reduce and simplify maintenance

- Reduce the cost of cooling your production

- Certified performance in accordance with AHRI regulations

Turn to efficiency

Alfa Laval plate heat exchangers can operate with the same small temperature difference as evaporators. To fully benefit this efficiency, we have developed the U-Turn separator. This efficient module is also very compact, and the connections are grouped to allow the module to be installed close to walls or on the perimeter of a main skid.

- Designed for natural ammonia refrigerant

- Minimum pressure drop losses, maximum energy efficiency

- Close temperature approach, space saving design

- Complete solution including our heat exchanger and separator technology

The benefits of the Alfa Laval U-turn

- Designed for natural refrigerants

- Complete solution including our plate heat exchanger and separator technology

- Minimum pressure drop losses

- Maximum energy efficiency

- Close temperature approach

- Space saving design

- Available for semi-welded-plate-heat-exchangers and Alfa Nova fusion bonded plate heat exchangers

Discover the future of green IT with Alfa Laval

Alfa Laval has supplied solutions for cooling server rooms since the earliest days of the internet. Today, we offer a wide range of solutions for data center cooling, all backed by a worldwide service network with experts who understand your business. By partnering with us as you begin planning your data center project, we can help you design a system that ensures you get maximum cooling efficiency and reliability.

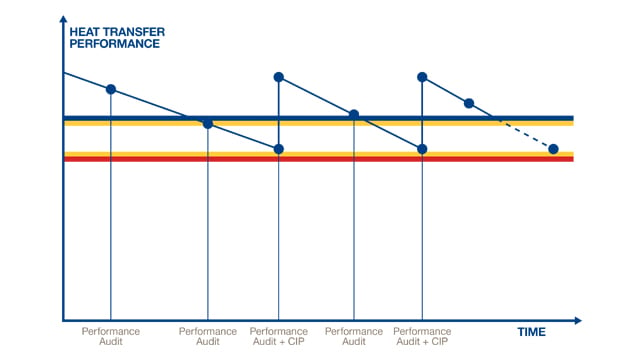

Audit performa

Pakar terlatih kami meninjau dan menganalisis performa termal sebenarnya dari peralatan Anda. Dengan menggunakan alat modern, para pakar dapat mendeteksi fouling atau risiko serupa, sehingga memungkinkan Anda merencanakan kebutuhan pemeliharaan secara lebih baik untuk mengoptimalkan waktu operasional sistem.

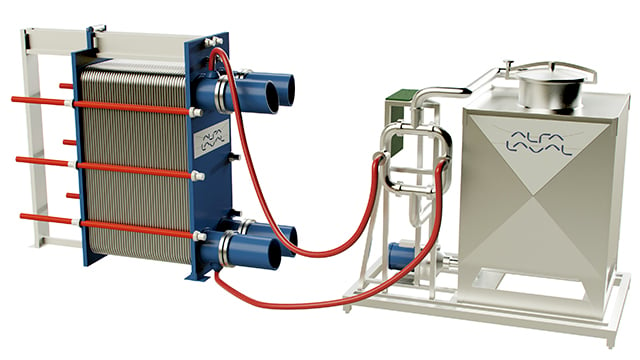

Pembersihan di tempat

Sistem pembersihan di tempat (CIP) Alfa Laval memungkinkan pembersihan in-line heat exchanger yang cepat dan mudah untuk mengelola fouling. Dengan bahan pembersih yang ramah lingkungan dan dapat terurai secara hayati, CIP kami meniadakan pembukaan berulang yang tidak perlu pada peralatan Anda. Hasilnya, Anda mengurangi penggunaan suku cadang dan jam kerja yang dibutuhkan untuk pemeliharaan secara drastis.

Backflushing

Alfa Laval merekomendasikan agar sering melakukan backflushing pada aliran air pendingin yang masuk untuk waktu yang singkat. Dalam urutan ini, air yang dialirkan berlawan arah dapat mengikis dan membuang kotoran yang terakumulasi di permukaan plate heat exchanger. Penggunaan peralatan backflush akan menghemat waktu dan uang, sekaligus meminimalkan waktu henti operasional.

Ready to learn more?

Want to find out how we can boost the cost efficiency and sustainability of your data center with smart cooling tower solutions based on leading plate heat exchanger technologies? Contact us today, and our experts will be in touch!